-

PDF

- Split View

-

Views

-

Cite

Cite

Bernard D. Goldstein, Bryan W. Brooks, Steven D. Cohen, Alexander E. Gates, Michael E. Honeycutt, John B. Morris, Jennifer Orme-Zavaleta, Trevor M. Penning, John Snawder, The Role of Toxicological Science in Meeting the Challenges and Opportunities of Hydraulic Fracturing, Toxicological Sciences, Volume 139, Issue 2, June 2014, Pages 271–283, https://doi.org/10.1093/toxsci/kfu061

Close - Share Icon Share

Abstract

We briefly describe how toxicology can inform the discussion and debate of the merits of hydraulic fracturing by providing information on the potential toxicity of the chemical and physical agents associated with this process, individually and in combination. We consider upstream activities related to bringing chemical and physical agents to the site, on-site activities including drilling of wells and containment of agents injected into or produced from the well, and downstream activities including the flow/removal of hydrocarbon products and of produced water from the site. A broad variety of chemical and physical agents are involved. As the industry expands this has raised concern about the potential for toxicological effects on ecosystems, workers, and the general public. Response to these concerns requires a concerted and collaborative toxicological assessment. This assessment should take into account the different geology in areas newly subjected to hydraulic fracturing as well as evolving industrial practices that can alter the chemical and physical agents of toxicological interest. The potential for ecosystem or human exposure to mixtures of these agents presents a particular toxicological and public health challenge. These data are essential for developing a reliable assessment of the potential risks to the environment and to human health of the rapidly increasing use of hydraulic fracturing and deep underground horizontal drilling techniques for tightly bound shale gas and other fossil fuels. Input from toxicologists will be most effective when employed early in the process, before there are unwanted consequences to the environment and human health, or economic losses due to the need to abandon or rework costly initiatives.

Disclaimer: Any statements, opinions, or conclusions contained herein do not necessarily represent the opinions, statements, or conclusions of EPA, NIEHS, NIH, or the U.S. Government.

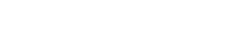

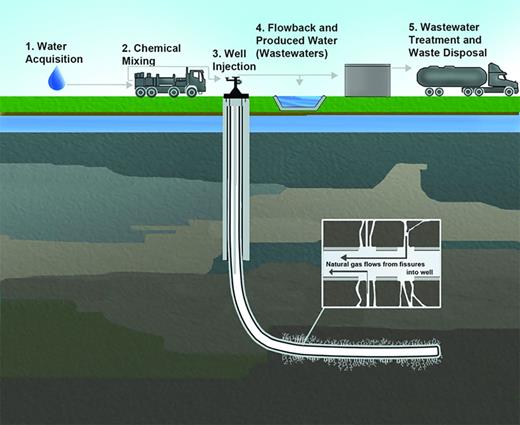

Advances in the technology of hydraulic fracturing of shale to produce natural gas and oil offers the United States welcome opportunities to enhance domestic energy options and promote energy independence. The efficiency of natural gas for electric power generation also provides the opportunity to reduce greenhouse gas emissions as well as decrease the level of toxic airborne pollutants. North America has vast reserves of natural gas and oil that are now commercially viable as a result of advances in engineering technology allowing directional horizontal drilling in shale layers deep underground, and advances in the perforation and injection of water containing chemical and physical agents to create permeability in rock formations that are relatively impermeable (Fig. 1). This permits the release of natural gas and oil tightly held within shale and other “tight” resources—a process known as hydraulic fracturing. The process makes use of a broad variety of chemical and physical agents which have raised public health concern, particularly as the industry expands (Adgate et al., 2014; Goldstein et al., 2012; Government of New Brunswick Canada, 2013; Korfmacher et al., 2013, Witter et al. 2008). A National Research Council elicitation of public concern found that those most commonly raised were groundwater contamination, air quality, poor regulations, and health impacts (Israel et al., 2013).

With the increasing use of such technologies, it is important to assess their potential environmental and human health consequences. Policymakers and the public are seeking assurance that the rapidly increasing hydraulic fracturing effort is being developed in a manner that maximizes benefits while minimizing risks to the environment and public health. Minimizing these risks requires a full understanding of the toxicology of chemical and physical agents used in or emitted as a result of the hydraulic fracturing process. Presently, insufficient data exist on the toxicity of individual compounds or fracturing fluid mixtures as formulated for injection or as recovered spent fluids for treatment and reuse or disposal. Complete understanding of the potential risks for some individual fluid components is hindered because certain constituents are considered proprietary or are described only as chemical classes. Thorough toxicological evaluation of the potential for adverse health impacts also includes consideration of likely exposure pathways to workers involved in the process, as well as to the general population, and terrestrial and aquatic ecosystems.

Hydraulic fracturing was developed from conventional oil and gas production, and as such many of the processes and chemicals involved have been the subject of earlier public, environmental and occupational health studies, and risk assessments. These will not be detailed in this document. Addressing these important health and environmental concerns requires collaboration between all stakeholders to sustainably develop this valuable energy resource so as to maximize its benefits while minimizing its environmental and public health risks.

This document was prepared at the request of the Council of the Society of Toxicology (SOT) by a working group chosen and convened by the SOT Council. SOT leadership is particularly interested in knowing how we can safely take advantage of this tremendous resource and ensure that public and environmental health will not be compromised. The working group was asked to:

Summarize what is known and not known about the potential risks to human health and the environment.

Identify research that should be considered in addressing health and environmental concerns.

Address the public's concerns about mixtures that are used in the process and agents that result from the backflow processes by exploring areas of regulation and/or disclosure or both.

A short unreferenced summary of this report was posted for comment by all SOT members on the SOT website.

The working group considered toxicological issues underlying a broader environmental health risk assessment, but did not focus on a toxicologically assessing each of the many hundreds of chemical and physical agents potentially involved in activities related to hydraulic fracturing. The working group also has not considered broader health-related issues associated with the current rapid growth in natural gas or oil production. These include health benefits from replacing coal, thereby reducing air pollution and potentially lessening greenhouse gas health impacts; and adverse effects, such as psychosocial impacts and other adverse health effects associated with boomtowns (Deutch, 2011; Jacquet and Stedman, 2013).

WHAT IS HYDRAULIC FRACTURING?

The process of hydraulic fracturing continues to evolve, particularly for natural gas and oil located in tightly bound shale layers. Basically, hydraulic fracturing involves injecting large volumes of water, sand, and chemicals into a drilled well at high pressure to produce an array of fractures primarily in shale formations at specific points to allow enhanced recovery of oil and gas. The sand or “proppant” is driven into these fractures to brace them open. The natural gas (and/or oil) can then flow into the well at an enhanced rate. Currently, 3–5.5 million gallons of water are used on average for hydraulic fracturing each time. A substantial amount of the water (estimates of 10–70%) flows back to the surface relatively rapidly. The rest is absorbed by the source rock. Much smaller amounts are produced continuously during the lifetime of the well. The term “produced water” can be used to describe all the fluid that returns from the well. Drill pads average about 3.5 acres, but some may be considerably larger. The fracturing operation for a single lateral run of a horizontal well typically takes 2–5 days, but may take more time for longer lateral wellbores (DOE Primer; NY DEC). Sequential hydraulic fracturing of upward of eight wells from the same drill pad can persist for months. The depth of the natural gas and oil production zones vary, but are commonly thousands of feet underground, which is far beneath groundwater aquifers.

THE MATERIALS USED IN HYDRAULIC FRACTURING

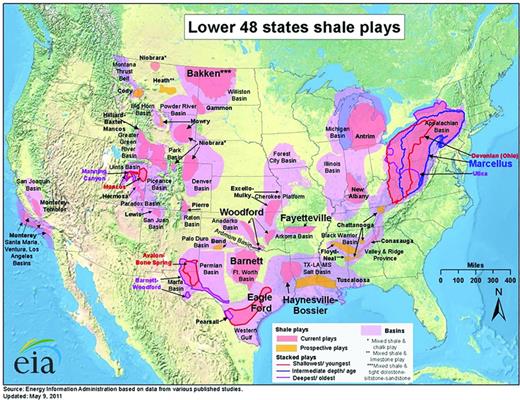

The most frequently used mixtures for fracturing shale to produce gas are ∼90% water and ∼9% proppant (typically sand) and the remainder consists of chemical additives comprising 0.5–2% by volume (Environmental Protection Agency, 2011). Chemical additives are used for a wide range of purposes including those classified as biocides, breakers, buffers, clay stabilizers, corrosion inhibitors, crosslinkers, foaming agents, friction reducers, gelling agents, iron control agents, pH adjusters, scale inhibitors, solvents, and surfactants (Department of Energy, 2009). Some chemicals are used for several purposes and not all purposes are disclosed for each chemical. Figure 2 shows the volumetric composition of a typical fracturing fluid, representing a fluid used in the Fayetteville Shale of Arkansas, USA (American Petroleum Institute, 2012; Department of Energy, 2009). Not all chemical functions are needed for every fracturing job and, although there are >1000 chemicals that have been used, only a limited number are routinely used. Depending upon state law and company practice, information about the hydraulic fracturing agents used in an individual well is often but not always obtainable.

Volumetric composition of typical fracturing fluid, Fayetteville, AR, USA.

FracFocus, a national hydraulic fracturing chemical registry, was created by participating oil and gas companies to respond to increasing concern about the potential health and environmental implications of fracturing fluids (fracfocus.org). It provides public access to lists of chemicals used in individual wells, although some chemicals are listed as proprietary. As of December 2012, FracFocus has recorded more than 33,000 voluntary well site disclosures from more than 430 participating companies listing over 600 different chemicals. Linkages are given to Environmental Protection Agency and Occupation Safety and Health Administration. sites that provide information about toxicity of the individual chemicals. The FracFocus site is being upgraded to permit searching across the database but impediments remain to downloading and working with aggregate data (Booth, 2013). In addition, many states have developed or are developing public disclosure rules related to hydraulic fracturing fluids. Disclosure of the natural components recovered in produced water or of any products of chemical reactions among the different agents is less likely to be available or required by state law.

With the rapid improvement of technology, the chemicals used in hydraulic fracturing are evolving over time. The specific agents can vary depending on the geological location and the drilling company. Accordingly, the potential human and environmental implications may differ greatly from site to site.

HYDROCARBONS RESULTING FROM SHALE AND OTHER TIGHT GAS DRILLING

Shale gas areas are usually divided into “dry” gas and “wet” gas, depending upon hydrocarbon content. Dry gas is almost totally methane with relatively little higher molecular weight product. Wet gas is also predominantly methane but contains a larger percentage of higher molecular weight compounds (crude oil or condensate), including benzene, toluene, ethylbenzene, and xylene (BTEX). Under current market conditions, wet gas is more valuable as it provides raw material for plastics and other chemical industry products. Methane itself is relatively nontoxic to humans and to ecosystems but is flammable and explosive (Pennsylvania Department of Health, 2011). It is also a substantial contributor to global climate change. Among the higher molecular weight wet gas components, benzene is a particular concern as it is a known cause of human leukemia and can be a contaminant of both air and water (International Agency for Research on Cancer, 2010). The hydrocarbon components of natural gas also serve to varying degrees as ground level ozone precursors.

PRODUCED WATER

The properties of produced water vary with geologic formation, fracturing fluid composition, and the time since drilling. The naturally present chemicals in the rocks that can be brought to the surface in the produced water may pose a concern. Known collectively as total dissolved solids (TDS), these are principally brine components of ancient seafloor or components that were later introduced to the rock through natural hydrothermal processes. The U.S. EPA reports that produced water can contain TDS at levels many times than those found in sea water (Environmental Protection Agency, 2011). These levels are often in excess of TDS discharge limits into surface water and at levels beyond most municipal water treatment facility permits. Depending on the formation fractured, produced water also can contain specific chemicals such as bromide, barium, calcium, copper, iron, magnesium, strontium, sulfur, and other naturally present agents such as arsenic, selenium, and radionuclides (Environmental Protection Agency, 2011; Pennsylvania State University, 2011) at concentrations that can exceed drinking water standards (Fontenot et al., 2013).

The identification of bromide in outflows from publicly owned treatment works (POTW), which had received produced water, has been of concern as chlorination of drinking water containing bromide will produce brominated compounds, such as dibromochloropropane, of potential toxicological significance (Ferrar et al., 2013a; Warner et al., 2013; Wilson and VanBriesen, 2012; Wilson et al., 2013). This has led to a switch from chlorine to chloramines for water disinfection purposes (Stolz, 2011) and an apparent cessation in Pennsylvania of the disposal of produced waters in Publicly Owned Treatment Works which has lessened the bromide content of receiving waters. The ensuing trucking of produced waters and injection into deep wells in Ohio has been linked to seismic activity (Choi, 2013).

Produced water may be recycled at the drilling site, particularly the fluid that comes back relatively quickly as it contains less TDS than the fluid sourced from deep underground. Off site recycling is increasing, and in some locations, such as Texas, the geology supports deep well injection. In other locations, such as Pennsylvania, disposition of produced water is more challenging. It may be stored on-site, contained in off-site collecting ponds or recycled. It should be noted that the use or absence of liners in the ponds can affect risk of water contamination.

Examples of common, naturally occurring substances that may be found in formations containing oil and gas are provided below in Table 1.

Common Naturally Occurring Substances Found in Formations Containing Oil and Gas

| Type of contaminant . | Examples . |

|---|---|

| Inorganics (or common ions) | Brine (e.g., sodium chloride, bromide) |

| Gases | Natural gas (e.g., methane, ethane), carbon dioxide, hydrogen sulfide, nitrogen, and helium |

| Trace elements | Mercury, lead, and arsenic |

| Naturally occurring radioactive material (NORM) | Radium, thorium, and uranium |

| Organic material | Organic acids, polycyclic aromatic hydrocarbons, volatile, and semivolatile organic compounds |

| Type of contaminant . | Examples . |

|---|---|

| Inorganics (or common ions) | Brine (e.g., sodium chloride, bromide) |

| Gases | Natural gas (e.g., methane, ethane), carbon dioxide, hydrogen sulfide, nitrogen, and helium |

| Trace elements | Mercury, lead, and arsenic |

| Naturally occurring radioactive material (NORM) | Radium, thorium, and uranium |

| Organic material | Organic acids, polycyclic aromatic hydrocarbons, volatile, and semivolatile organic compounds |

| Type of contaminant . | Examples . |

|---|---|

| Inorganics (or common ions) | Brine (e.g., sodium chloride, bromide) |

| Gases | Natural gas (e.g., methane, ethane), carbon dioxide, hydrogen sulfide, nitrogen, and helium |

| Trace elements | Mercury, lead, and arsenic |

| Naturally occurring radioactive material (NORM) | Radium, thorium, and uranium |

| Organic material | Organic acids, polycyclic aromatic hydrocarbons, volatile, and semivolatile organic compounds |

| Type of contaminant . | Examples . |

|---|---|

| Inorganics (or common ions) | Brine (e.g., sodium chloride, bromide) |

| Gases | Natural gas (e.g., methane, ethane), carbon dioxide, hydrogen sulfide, nitrogen, and helium |

| Trace elements | Mercury, lead, and arsenic |

| Naturally occurring radioactive material (NORM) | Radium, thorium, and uranium |

| Organic material | Organic acids, polycyclic aromatic hydrocarbons, volatile, and semivolatile organic compounds |

POTENTIAL PATHWAYS OF CONTAMINATION AND TOXICOLOGICAL EFFECTS

Potential sources of water pollution

Surface or groundwater contamination by hydraulic fracturing fluids and their constituents can result from incidents related to delivery of the agents to the site, storage and transfer, the injection process, and the eventual disposal of the produced waters (Fig. 3). Potential issues include accidental spills or leaks during transportation, from storage tanks, surface impoundment failures, leaching, overfills, vandalism, or improper operations including well failure (Environmental Protection Agency, 2011; Warner et al., 2013). As a result, fluids could contaminate nearby surface waters or migrate to groundwater. In areas of shallow production, the induced fracture array may release natural gas, crude oil, and other fracture-related fluids into an overlying aquifer thus compromising the water quality. However, there are currently few confirmed cases of groundwater contamination. Natural migration of hydraulic fracturing agents from deep brine layers to shallow aquifers has been recently suggested as a possible source of contamination (Warner et al., 2013).

Careful management of produced water is required, especially in areas containing sensitive groundwater resources. Potential exposure routes to aquatic and terrestrial ecosystems require careful consideration. Alteration of landscape features with resultant effects on terrestrial ecosystems also needs to be considered. Further, increased oil and gas development using hydraulic fracturing technology can modify watersheds and adversely affect water availability, which may be important in semiarid, drought-susceptible, and humid areas.

Produced water flowing back to the surface through the well bore must also be carefully contained at the site and through subsequent disposal processes. Groundwater contamination, from fracturing fluids or produced water, depends on the site-, chemical-, and fluid-specific factors such as physical characteristics of the site and the spill. Fluid specific factors include chemical and physical properties of the additives in the fluids that affect mobility in soils and other media as well as other fate and transport characteristics.

A major issue has been whether methane identified in well water comes from nearby hydraulic fracturing activities or older conventional wells (thermogenic methane) or is present due to subsurface coal bed methane, bacterial decomposition (methanogenic bacteria), or other sources (American Petroleum Institute, 2012; Davies, 2011; Jackson et al., 2013; Osborn et al., 2011). For shale gas, methane serves as an indicator for other higher molecular weight components. A recent study suggesting that groundwater contamination from drilling sites in the Marcellus Shale found that ethane was more highly correlated with proximity to a natural gas well site than was methane (Jackson et al., 2013). Similarly, a recent study in the Barnett Shale area reported that private drinking water wells in proximity to active natural gas wells were more likely to have levels of TDS, arsenic, selenium, and strontium that exceeded EPA's maximum contaminant limit (Fontenot et al., 2013). The authors could not distinguish between potential sources and, as with the current data in general, there appeared to be lack of baseline information as to water quality before shale gas drilling began. Accordingly, aside from industrial incidents, such as the loss of well integrity, in the absence of analysis of drinking and surface waters conducted before the onset of drilling there is little sound evidence of contamination with toxicologically significant levels of chemicals as a result of routine hydraulic fracturing for tightly bound shale gas. Predrilling sampling and analysis should be required to provide adequate background information for comparison with data collected at the same sites during the hydraulic fracturing operation.

Potential sources of air pollution

Sources of air pollution as a result of direct activities associated with the hydraulic fracturing process include release of methane gas at well heads, controlled burning of natural gas (flaring), and the presence of volatile organic chemicals (VOCs) in the produced water that can evaporate from storage in open pits (see Table 2). VOCs include BTEX which may add inherent toxicological risks and, when reacting with nitrogen oxides (NOx) and sunlight, can also increase ground level ozone. Ozone is well known to exacerbate asthma and chronic obstructive pulmonary disease (COPD) due to increases in airway sensitivity. Epidemiological evidence that relatively low levels of ozone may lead to an increase in mortality is leading EPA to consider a more stringent ozone standard. A single hydraulic fracturing site is unlikely to produce significant increments of ozone precursors. However, there is concern that in aggregate hydraulic fracturing activities in regions with thousands of wells, and which already have ozone levels close to the allowable health-based standard, such as the Northeast, may be tipped into nonattainment of the standard (Robinson, 2012). An increase in ozone levels attributable to shale gas development has been projected by environmental models in Northeast Texas and Northern Louisiana as a result of hydraulic fracturing of the Haynesville Shale (Kemball-Cook et al., 2010). However, there has been a decline in ozone levels in the Barnett Shale area despite the drilling of over 16,000 wells (Honeycutt, 2012). Rand has modeled an increase in ozone precursors leading to health impacts and resultant economic impacts in Pennsylvania (Litovitz et al., 2013). They note that NOx emissions from the aggregate of shale gas activities in local areas were 20–40 times higher than allowable for a single minor source. Exceedance of the ozone standard during the winter in rural areas of Wyoming also has been ascribed to drilling-related activities (Stoeckenius and Ma, 2010).

Potential Health Effects of Air Pollutants Associated with Shale Gas Development

| Pollutant . | Potential health effects . |

|---|---|

| Methane | • Explosion and fire |

| • Asphyxiation in confined space | |

| • Global climate change | |

| Nonmethane volatile organic compounds including BTEXa | • Ozone precursors |

| • Leukemia and other hematological effects (benzene, formaldehyde) | |

| • Upper respiratory tract inflammation | |

| • Central nervous system effects in confined spaces | |

| Oxides of nitrogen | • Ozone precursors |

| • Asthma and other acute respiratory effects | |

| Ozone including photochemical oxidants | • Asthma and other acute respiratory effects |

| • Loss of lung function | |

| • Premature mortality | |

| Particulates including diesel exhaust | • Asthma and other acute and chronic respiratory effects |

| • Premature mortality | |

| • Cancer | |

| Silica dust | • Chronic lung disease (silicosis; particularly among workers) |

| Pollutant . | Potential health effects . |

|---|---|

| Methane | • Explosion and fire |

| • Asphyxiation in confined space | |

| • Global climate change | |

| Nonmethane volatile organic compounds including BTEXa | • Ozone precursors |

| • Leukemia and other hematological effects (benzene, formaldehyde) | |

| • Upper respiratory tract inflammation | |

| • Central nervous system effects in confined spaces | |

| Oxides of nitrogen | • Ozone precursors |

| • Asthma and other acute respiratory effects | |

| Ozone including photochemical oxidants | • Asthma and other acute respiratory effects |

| • Loss of lung function | |

| • Premature mortality | |

| Particulates including diesel exhaust | • Asthma and other acute and chronic respiratory effects |

| • Premature mortality | |

| • Cancer | |

| Silica dust | • Chronic lung disease (silicosis; particularly among workers) |

aBTEX: benzene, toluene, ethyl benzene, and xylenes.

| Pollutant . | Potential health effects . |

|---|---|

| Methane | • Explosion and fire |

| • Asphyxiation in confined space | |

| • Global climate change | |

| Nonmethane volatile organic compounds including BTEXa | • Ozone precursors |

| • Leukemia and other hematological effects (benzene, formaldehyde) | |

| • Upper respiratory tract inflammation | |

| • Central nervous system effects in confined spaces | |

| Oxides of nitrogen | • Ozone precursors |

| • Asthma and other acute respiratory effects | |

| Ozone including photochemical oxidants | • Asthma and other acute respiratory effects |

| • Loss of lung function | |

| • Premature mortality | |

| Particulates including diesel exhaust | • Asthma and other acute and chronic respiratory effects |

| • Premature mortality | |

| • Cancer | |

| Silica dust | • Chronic lung disease (silicosis; particularly among workers) |

| Pollutant . | Potential health effects . |

|---|---|

| Methane | • Explosion and fire |

| • Asphyxiation in confined space | |

| • Global climate change | |

| Nonmethane volatile organic compounds including BTEXa | • Ozone precursors |

| • Leukemia and other hematological effects (benzene, formaldehyde) | |

| • Upper respiratory tract inflammation | |

| • Central nervous system effects in confined spaces | |

| Oxides of nitrogen | • Ozone precursors |

| • Asthma and other acute respiratory effects | |

| Ozone including photochemical oxidants | • Asthma and other acute respiratory effects |

| • Loss of lung function | |

| • Premature mortality | |

| Particulates including diesel exhaust | • Asthma and other acute and chronic respiratory effects |

| • Premature mortality | |

| • Cancer | |

| Silica dust | • Chronic lung disease (silicosis; particularly among workers) |

aBTEX: benzene, toluene, ethyl benzene, and xylenes.

Air pollution also occurs with the use of diesel engines in drilling, from natural gas compressor stations and due to the large number of diesel trucks that may be required to make each drill head operational. For certain sites, it is estimated that up to 1700 diesel trucks are required to deliver the 5 million gallons of water required to fracture a well, and that another 750 diesel trucks are required to deliver the 1.5 million pounds of proppant—often over a period of a few weeks. These estimates do not include the diesel truck delivery of hydraulic fracturing chemicals, drill rigs, or well casing nor do they include trips to remove the natural gas, oil, or wastewater. Many of the diesel engines involved likely predate 2007 when there was a switch to new, less polluting diesel technology. Diesel exhaust has been associated with an increased risk of childhood asthma and other respiratory diseases and, based upon studies of workers exposed to older diesel technology, is carcinogenic in humans (Benbrahim-Tallaa et al., 2012). Ongoing industry transition to new, less polluting diesel fuels and to natural gas for vehicles and other equipment used in the hydraulic fracturing process should lessen this source of pollution.

A study of air emissions from shale gas development in Colorado predicted a cumulative increase of 6–10 per million incidences for lifetime cancer risk from benzene, depending on residential distance from the site (McKenzie et al., 2012). The study also predicted increases of risk other than cancer primarily from exposure to trimethylbenzenes, xylenes, and aliphatic hydrocarbons. Alternatively, a human health benefit associated with hydraulic fracturing is that increasing availability of natural gas for energy production lessens exposures to particulates, polycyclic aromatic hydrocarbons (PAHs), mercury, and other known air pollutants by replacing coal as a fuel source.

The Texas Commission on Environmental Quality (TCEQ) used flyovers of helicopters outfitted with infra-red (IR) cameras capable of visualizing VOC emissions, conducted numerous mobile monitoring trips, and has installed an extensive ambient air fixed-site monitoring system in areas with intensive drilling. Between 1 August 2009 and 30 June 2012, the TCEQ surveyed 2307 sites in the Barnett Shale area using hand-held IR cameras, and at 2263 of these sites, hand-held survey instruments were also used. These surveys included citizen complaint investigations, compliance investigations, mobile monitoring trips, and follow-up investigations based on helicopter flyovers. As a result of observations with the hand-held IR camera and measurements collected using the survey instruments, 1167 short-term field canister samples were collected and analyzed for VOCs. Of those, seventeen VOC canister samples measured elevated short-term levels of chemicals associated with natural gas operations (benzene, alkanes, etc.) near facilities that were not operating properly. Short-term samples have also been collected and analyzed for carbonyls, NOx, and sulfur compounds and none of the analyses have detected chemicals at short-term levels of concern. Six stationary VOC monitors were operational in the Barnett Shale area in 2009, 21 are operational as of September 2013. No VOCs have been detected to date at levels of long-term health concern (Bunch et al., 2014; Honeycutt, 2012).

A recent study of methane emissions by Allen et al. (2013), working with cooperating industries in different parts of the United States, raises the possibility of local pollution, particularly in wet gas areas. The authors found wide variation from site to site, including in adjacent sites drilled by the same company. Methane emissions during the flowback period immediately following hydraulic fracturing ranged from 0.01 to 17 Mg. Further, there was about a 100-fold variation in emissions during uploading events in which the producing well is subject to relatively sudden hydrocarbon releases. This same variability would be anticipated for BTEX or other VOCs, suggesting that local hot spots of air pollutants during short time periods might exist.

Chemical/Physical Exposure Hazards by Type of Operation (Identified in Prior NIOSH Research)

| Operation . | Silica . | DPMa . | VOCsb/BTEXc . | H2S . | PAHd . | Biocides/Misc.e . | Metals/NORMf . | Flammable . | Physical hazardsg . |

|---|---|---|---|---|---|---|---|---|---|

| Pad construction | X | X | X | X | X | ||||

| Drilling | X | X | X | X | X | X | X | X | X |

| Cementing | X | X | X | X | X | X | X | X | X |

| Stimulation/fracturing | X | X | X | X | X | X | X | X | X |

| Well testing/completion | X | X | X | X | X | X | X | X | |

| Well servicing | X | X | X | X | X | X | X | ||

| Trucking | X | X | X | X | X | X | X | X |

| Operation . | Silica . | DPMa . | VOCsb/BTEXc . | H2S . | PAHd . | Biocides/Misc.e . | Metals/NORMf . | Flammable . | Physical hazardsg . |

|---|---|---|---|---|---|---|---|---|---|

| Pad construction | X | X | X | X | X | ||||

| Drilling | X | X | X | X | X | X | X | X | X |

| Cementing | X | X | X | X | X | X | X | X | X |

| Stimulation/fracturing | X | X | X | X | X | X | X | X | X |

| Well testing/completion | X | X | X | X | X | X | X | X | |

| Well servicing | X | X | X | X | X | X | X | ||

| Trucking | X | X | X | X | X | X | X | X |

aDiesel particulate matter and other combustible products (NOx/CO/SOx).

bVolatile organic compounds.

cBenzene, toluene, ethylbenzene, and xylene.

dPolycyclic aromatic hydrocarbons.

eAldehydes, acids, bases, alcohols, surfactants, alcohols, lube oils, and greases.

fNormal occurring radioactive materials.

gNoise, heat, and cold.

| Operation . | Silica . | DPMa . | VOCsb/BTEXc . | H2S . | PAHd . | Biocides/Misc.e . | Metals/NORMf . | Flammable . | Physical hazardsg . |

|---|---|---|---|---|---|---|---|---|---|

| Pad construction | X | X | X | X | X | ||||

| Drilling | X | X | X | X | X | X | X | X | X |

| Cementing | X | X | X | X | X | X | X | X | X |

| Stimulation/fracturing | X | X | X | X | X | X | X | X | X |

| Well testing/completion | X | X | X | X | X | X | X | X | |

| Well servicing | X | X | X | X | X | X | X | ||

| Trucking | X | X | X | X | X | X | X | X |

| Operation . | Silica . | DPMa . | VOCsb/BTEXc . | H2S . | PAHd . | Biocides/Misc.e . | Metals/NORMf . | Flammable . | Physical hazardsg . |

|---|---|---|---|---|---|---|---|---|---|

| Pad construction | X | X | X | X | X | ||||

| Drilling | X | X | X | X | X | X | X | X | X |

| Cementing | X | X | X | X | X | X | X | X | X |

| Stimulation/fracturing | X | X | X | X | X | X | X | X | X |

| Well testing/completion | X | X | X | X | X | X | X | X | |

| Well servicing | X | X | X | X | X | X | X | ||

| Trucking | X | X | X | X | X | X | X | X |

aDiesel particulate matter and other combustible products (NOx/CO/SOx).

bVolatile organic compounds.

cBenzene, toluene, ethylbenzene, and xylene.

dPolycyclic aromatic hydrocarbons.

eAldehydes, acids, bases, alcohols, surfactants, alcohols, lube oils, and greases.

fNormal occurring radioactive materials.

gNoise, heat, and cold.

Occupational exposures associated with upstream oil and gas production (see Table 3)

Safety issues are the major concern for oil and gas workers (Mode and Conway, 2008). Recent NIOSH research found that during 2003–2009, 716 oil and gas extraction workers were fatally injured on the job, resulting in an annual occupational fatality rate of 27.0 per 100,000 workers, more than seven times as high as in all U.S. industries (3.9), and nearly equal to the fatality rate in the agriculture, forestry, and fishing sector (30.7) (Retzer and Hill, 2011; Bureau of Labor Statistics, 2009). Small companies (65.5/100,000; <20 workers) were found to have a fatality rate higher than medium (23.4; 20–99 workers) and large companies (13.4; ≥100 workers) (Mode and Conway, 2008). Motor vehicle crashes are the leading cause of death to oil and gas extraction workers accounting for nearly 30% of all work-related fatalities; followed by workers being struck by objects (20%).

Very little data presently exists characterizing the toxicological hazards associated with hydraulic fracturing. Most studies of petroleum exposed workers have investigated downstream processes such as refining, manufacturing, and processing of petrochemical products, rather than exploration and production activities (drilling, servicing, and workover operations). Niven and McLeod (2009), in a review of hazards associated with the upstream petroleum industry, reported that limited epidemiological studies suggested an increased risk for leukemia and other hematopoietic cancers. Divine and Hartman (2000) in a large cohort study of crude oil production and pipeline workers found slight increases for cancer of the prostate, brain and central nervous system and lymphatic tissue, and a significant increase in acute myelogenous leukemia in workers employed prior to 1940 and who had 30 years of employment. One study that did investigate exploration and production operations found an increased risk for testicular cancer among workers employed in the extraction field (Mills et al., 1984). No published studies are available of the health of workers involved specifically in the recent upsurge of shale and oil drilling using hydraulic fracturing.

Verma et al. (2000) summarized data from over 1500 short- and long-term personal and area air samples for benzene and total petroleum hydrocarbons in the Canadian upstream oil and gas industry. Exposures were characterized by task, job description, and industry sector when possible. The authors reported that overall occupational exposure limits on a time-weighted average during work shifts were rarely exceeded for benzene and petroleum hydrocarbons, however, short-term measurements at times exceeded the occupational exposure limits; exposures were frequent and specific jobs with higher exposures were identified. Exposure to chemical hazards of workers who deal with product distribution terminals, truck, rail, and marine transportation can occur primarily by inhalation, and secondarily through dermal exposure; some other routes can include oral, contact with the eyes and because certain fluids such as hydraulic fracturing fluids, are under high pressure, these can be injected through the skin. Dermal exposure can lead to skin irritation and contact dermatitis (sensitization) which accounts for 10–15% of chemically induced occupational illnesses in oil and gas workers (World Health Organization, 2009), although specific data for shale gas workers is not available. Potential problems include hydrocarbon-induced neurotoxicity and pulmonary effects, including respiratory irritation and chemical pneumonitis caused by deposition of hydrocarbon droplets in the lungs. The potential adverse consequences of toxicologic interactions with the evolving list of hydraulic fracturing agents warrants consideration.

The use of silica as a proppant presents a hazard that is relatively specific for hydraulic fracturing. Results from an on-going NIOSH study, have shown that respirable crystalline silica exposures at hydraulic fracturing sites are largely uncontrolled (with the exception of use of respirators). NIOSH field research has shown that personal breathing zone silica concentrations for certain job titles that are in close proximity to sources of airborne silica dusts regularly exceed OSHA and NIOSH occupational health criteria and often exceed the maximum use concentration for both half-mask and in some cases even full-face air purifying respirators (Esswein et al., 2013). This research has resulted in the publication of a National Institute of Occupational Safety and Health Hazard Alert (2012) and cooperative programs between government, industry, manufacturers, and others to develop interim guidelines to educate employers and employees about the hazard, develop practical immediate interim solutions to control exposures, and design retrofits for existing equipment and modify new equipment with engineering controls (Snawder et al., 2013). Potential exposures of concern identified by NIOSH include periodic exposures to hydrocarbons. Other exposures of concern that lack sufficient characterization include diesel particulate, hydrogen sulfide, and biocides. Of particular concern is the combination of multiple exposures such as silica and diesel particulate matter, both of which the target lungs.

Radiation and noise

Rock units that contain hydrocarbons also typically contain naturally occurring radioactive material (NORM), particularly uranium and thorium. These elements and their decay products, notably radium-226 and radium-228, can be brought to the surface in drill cuttings and produced water. Radon-222, a gaseous decay product of radium, can be distributed in pipelines along with the natural gas. There is controversy over the possibility that relatively high levels of radon in natural gas from the Marcellus Shale located in the northeastern United States. can persist in the gas during travel to home usage and lead to an increase in lung cancer (Resnikoff, 2012a,b; Almaskut et al., 2012). Noise pollution has been noted as a source of community and individual concern (Ferrar et al., 2013b); but has not been systematically studied.

Sustainable environmental quality and water reuse

Aquatic ecosystems may be at particular risk to the high brine content of produced waters (Palomar and Losada, 2011). It is possible that constituents of hydraulic fracturing fluids could degrade environmental quality directly or indirectly by modifying aquatic habitats (Weltman-Fahs and Taylor, 2013), for example, by increasing the likelihood of harmful algae blooms (Brooks et al.2011). It has also been suggested that ground water contamination may impact the health of farm animals and pets, and that they may be sentinels for the effects in humans (Bamberger and Oswald, 2012). Additional studies are needed to determine whether such effects can be verified. Likewise, information on the ecotoxicology of hydraulic fracturing fluids is needed to characterize potential hazards and risks should the fluids be released to the environment.

Careful management of return fluids by methods other than deep well injection is required, especially in areas containing sensitive groundwater resources. The potential for interactions among surface waters and terrestrial ecosystems needs to be considered. Incidents where there may be exposure routes to aquatic and terrestrial ecosystems require further understanding. (Bowen and Farag, 2013). Further, watersheds are being modified in areas experiencing rapid exploitation of natural gas (e.g., Barnett Shale) particularly in semiarid and drought-susceptible areas where water availability may be affected. Other activities that particularly affect ecosystems include the transportation infrastructure such as access roads, product pipelines, and port facilities. The peer-reviewed literature does not examine whether such modifications to landscapes could result in adverse effects on wildlife habitats or increased runoff of storm water contaminants (e.g., sediments, nutrients, potential spills on gas pads). Ecosystem restoration goals and strategies are lacking.

Robust environmental assessment approaches are required to understand the potential impacts of beneficial reuse of hydraulic fracturing fluids for industrial, agricultural, potable, and habitat augmentation uses. Here again, sound scientific approaches employing toxicology will be critical for developing risk-based water reuse guidelines for hydraulic fracturing fluid.

TOXICOLOGICAL RESEARCH ACTIVITIES AND NEEDS

Central to the ability of toxicological science to provide the necessary information on the chemical and physical agents associated with hydraulic fracturing is understanding of the pathways and levels of exposure to facilitate an accurate assessment of potential risks. Table 4 provides a listing of the types of water-related research required to learn more about potential health effects associated with hydraulic fracturing activities.

Exposure-Related Research Needs Water

| Effectiveness of management strategies for ecosystem protection and conservation. |

| Determine what are typical mixtures of chemicals in HF fluids and what is the variability across the industry. |

| Identify and quantify by geologic area naturally occurring substances released during HF operations. |

| Determine the chemicals, physical properties of HF chemicals and chemicals in HF wastewaters. |

| Determine fate and transport of HF chemicals in the environment for various soil types. Include hydrologic properties, mass balance of constituents. |

| Identify constituents of produced water and their fate and transport in the environment. |

| Determine the potential for exposure from spills involving HF chemicals, produced waters, or wastewaters. |

| Determine potential for cumulative exposures related to refracturing existing wells. |

| Determine under what conditions HF chemicals can migrate to underground drinking water sources and how different types of geology affect this. |

| Develop exposure models to determine exposures to populations served by groundwater drinking water sources, or surface water supplied drinking water that could be contaminated by HF activities. |

| Develop monitoring strategies and chemical fingerprints, HF chemical, and wastewater constituents for source water and drinking water. |

| Determine the occurrence and severity of spills at HF sites. |

| Determine whether exposures are reduced by wastewater treatment of HF chemicals or naturally occurring substances released by HF operations in produced waters. |

| Effectiveness of management strategies for ecosystem protection and conservation. |

| Determine what are typical mixtures of chemicals in HF fluids and what is the variability across the industry. |

| Identify and quantify by geologic area naturally occurring substances released during HF operations. |

| Determine the chemicals, physical properties of HF chemicals and chemicals in HF wastewaters. |

| Determine fate and transport of HF chemicals in the environment for various soil types. Include hydrologic properties, mass balance of constituents. |

| Identify constituents of produced water and their fate and transport in the environment. |

| Determine the potential for exposure from spills involving HF chemicals, produced waters, or wastewaters. |

| Determine potential for cumulative exposures related to refracturing existing wells. |

| Determine under what conditions HF chemicals can migrate to underground drinking water sources and how different types of geology affect this. |

| Develop exposure models to determine exposures to populations served by groundwater drinking water sources, or surface water supplied drinking water that could be contaminated by HF activities. |

| Develop monitoring strategies and chemical fingerprints, HF chemical, and wastewater constituents for source water and drinking water. |

| Determine the occurrence and severity of spills at HF sites. |

| Determine whether exposures are reduced by wastewater treatment of HF chemicals or naturally occurring substances released by HF operations in produced waters. |

| Effectiveness of management strategies for ecosystem protection and conservation. |

| Determine what are typical mixtures of chemicals in HF fluids and what is the variability across the industry. |

| Identify and quantify by geologic area naturally occurring substances released during HF operations. |

| Determine the chemicals, physical properties of HF chemicals and chemicals in HF wastewaters. |

| Determine fate and transport of HF chemicals in the environment for various soil types. Include hydrologic properties, mass balance of constituents. |

| Identify constituents of produced water and their fate and transport in the environment. |

| Determine the potential for exposure from spills involving HF chemicals, produced waters, or wastewaters. |

| Determine potential for cumulative exposures related to refracturing existing wells. |

| Determine under what conditions HF chemicals can migrate to underground drinking water sources and how different types of geology affect this. |

| Develop exposure models to determine exposures to populations served by groundwater drinking water sources, or surface water supplied drinking water that could be contaminated by HF activities. |

| Develop monitoring strategies and chemical fingerprints, HF chemical, and wastewater constituents for source water and drinking water. |

| Determine the occurrence and severity of spills at HF sites. |

| Determine whether exposures are reduced by wastewater treatment of HF chemicals or naturally occurring substances released by HF operations in produced waters. |

| Effectiveness of management strategies for ecosystem protection and conservation. |

| Determine what are typical mixtures of chemicals in HF fluids and what is the variability across the industry. |

| Identify and quantify by geologic area naturally occurring substances released during HF operations. |

| Determine the chemicals, physical properties of HF chemicals and chemicals in HF wastewaters. |

| Determine fate and transport of HF chemicals in the environment for various soil types. Include hydrologic properties, mass balance of constituents. |

| Identify constituents of produced water and their fate and transport in the environment. |

| Determine the potential for exposure from spills involving HF chemicals, produced waters, or wastewaters. |

| Determine potential for cumulative exposures related to refracturing existing wells. |

| Determine under what conditions HF chemicals can migrate to underground drinking water sources and how different types of geology affect this. |

| Develop exposure models to determine exposures to populations served by groundwater drinking water sources, or surface water supplied drinking water that could be contaminated by HF activities. |

| Develop monitoring strategies and chemical fingerprints, HF chemical, and wastewater constituents for source water and drinking water. |

| Determine the occurrence and severity of spills at HF sites. |

| Determine whether exposures are reduced by wastewater treatment of HF chemicals or naturally occurring substances released by HF operations in produced waters. |

Understanding exposure pathways so as to predict worker, community, and ecosystem effects requires a broad evaluation of all activities, including the trucking of materials to and from the site, all efforts at the site, and the disposition of the produced water. It will be beneficial to include measurements of air, water, and soil, and of biological markers of exposure and effect in ecosystems and humans. Exposure assessments should be coupled with toxicological studies of the potential impacts using accepted toxicological methodologies as well as newer computational modeling approaches. Particular attention needs to be paid to mixtures of agents for which exposure is identified or likely. Rapidly advancing toxicological techniques based upon molecular and computational toxicology, such as ToxCast, are ripe to be applied to understanding the challenge posed by mixtures potentially associated with hydraulic fracturing. (ToxCast http://www.epa.gov/ncct/toxcast/; NRC 2007). Recent approaches to combinatorial toxicology have focused on understanding the modes and mechanisms of action of individual components. Applying the fundamental principles of toxicological risk assessment to chemical combinations has led to schemes which consider four different possibilities: (1) similar actions in which the individual chemicals do not influence each other's toxicity and the effects of mixtures can be estimated from the dose of individual components; (2) dissimilar actions in which the individual chemicals do not influence each other's toxicity and the effects of the mixtures can estimated by summation of the biological responses; (3) toxicological interactions in which individual chemicals influence the toxicokinetic, metabolic, or toxicodynamic effects at target molecules of other chemical in the mixture; and (4) the production of chemical reactions among components of the mixture requiring toxicological evaluation of the novel products (European Commission, 2011; World Health Organization, 2009, 2011). All four of these possible modes of interaction should be evaluated in relation to hydraulic fracturing.

Chemicals need to be identified and subjected to preliminary exposure and risk assessment estimates. The agents to be considered include those used in hydraulic fracturing; the petroleum and formation fluids such as natural gas components in the rock units and other naturally occurring compounds brought to the surface as part of the process. Such assessments should also include the potential impact of agents identified as endocrine disruptors because one published report has suggested that many of the hydraulic fracturing compounds may be endocrine disruptors, but no consideration was given to dose in that report (Colborn et al., 2011). Herein, robust assessments employing adverse outcome pathway approaches (Ankley et al., 2010) would be particularly useful.

Green chemistry principles (i.e., sustainable molecular design of less toxic substances; Voutchkova et al., 2011; Voutchkova-Kostal et al., 2012), and similar alternative analyses appear useful for the suite of chemicals currently used in fracturing fluids (Anastas and Warner, 1998).

The few epidemiological studies published, whether or not reporting an association of adverse consequences with hydraulic fracturing, have evaluated a broad range of outcomes or have not had sufficient power or specificity to serve as a guide for planning toxicological studies (Ferrar et al., 2013b; Fryzek et al., 2013; Steinzor et al., 2013).

Finally, but most importantly, toxicological evaluation of chemical and physical agents associated with hydraulic fracturing should be accelerated. As described below, EPA has a study under way to identify chemicals used in hydraulic fracturing and to compile high quality information regarding the chemical, physical, and toxicological properties of the chemicals. EPA's work is not designed to consider issues such as mixtures. One of the most difficult challenges facing toxicologists is predicting the effects of mixtures. Adding to this challenge is that the mixtures will vary from location to location based upon the choice of hydraulic fracturing agents as well as local geology, which will determine hydrocarbon and natural background constituents. Special attention needs to be paid to potential toxicity occurring due to the interaction of these many compounds in producing adverse health effects. In addition, the possibility of chemical reactions among the diverse components producing unwanted chemical products requires consideration.

Continued development and validation of predictive models and tiered assessment approaches for complex mixtures are warranted to move the field forward. This will permit better definition of the relative risks associated with exposures to the complex mixtures of chemicals used in hydraulic fracturing processes, and thereby provide information that will be important to minimizing any negative impact of this enterprise on human and environmental health. The science of toxicology and the professionals who study mechanisms of toxicity and carry out complex risk assessments associated with chemical evaluation need to be part of the state and federal advisory committees that are tasked with responding to the potential health impacts of shale gas drilling (Goldstein et al., 2012). Addressing these important health and environmental topics requires collaboration between all stakeholders to sustainably develop this valuable energy resource so as to maximize its benefits while minimizing its environmental and public health risks.

Given the potential for accidental human exposure due to spills, industrial accidents, improper wastewater treatment and handling, and potential seepage, it is important to understand the known and potential hazards posed by the diversity of chemicals used during hydraulic fracturing. In addition to actively considering investigator-initiated research proposals, a number of federal agencies have research in progress specifically addressing environmental and public health issues associated with hydraulic fracturing for oil and gas.

EPA has embarked on a long-term study of the potential impacts of hydraulic fracturing on drinking water resources, including a focus on understanding the known and potential hazards posed by the diversity of chemicals used during hydraulic fracturing. The U.S. EPA has compiled a list of ∼1000 chemicals that have been used as additives (Appendix E, Environmental Protection Agency, 2011). EPA's study includes requested data from nine service companies for information on the identity of chemicals used in their hydraulic fracturing fluid from 2005 to 2009 and for well records from nine oil and gas companies whose wells had been fractured by the nine service companies during 2009–2010.

As noted in EPA's Progress Report (Environmental Protection Agency, 2012) existing data are being gathered regarding toxicity and potential human health effects associated with the chemicals reported to be in fracturing fluids and found in wastewater. At this time, EPA has not made any judgment about the extent of exposure to these chemicals when used in hydraulic fracturing fluids or found in hydraulic fracturing wastewater, or their potential impacts on drinking water resources. The EPA is compiling existing high quality information on chemical, physical, and toxicological properties of hydraulic fracturing-related chemicals. This work will inform answers to the research questions specifically listed in the progress report (Environmental Protection Agency, 2012).

The identification of inherent chemical properties will facilitate the development of models to predict environmental fate, transport, and the toxicological properties of chemicals. Through this level of understanding, scientists can design or identify more sustainable alternative chemicals that minimize or even avoid many fate, transport, and toxicity issues, while maintaining or improving commercial use. For example, the recently initiated NSF/EPA Networks for Sustainable Molecular Design and Synthesis appear poised to contribute to meeting such needs (http://www.nsf.gov/news/news_summ.jsp?cntn_id=129235).

The EPA must understand (1) potential hazards inherent to the chemicals being used in or released by hydraulic fracturing and returning to the surface in produced water, (2) dose-response characteristics, and (3) potential exposure levels in order to assess the potential impacts to human health from ingestion of drinking water that might contain the chemicals. The information from the toxicity assessment project provides a foundation for future risk assessments. Although the EPA currently does not have plans to conduct a formal risk assessment on this topic, the information may aid others who are investigating the risk from exposure.

The National Toxicology Program (NTP) within NIEHS carries out toxicology research and testing on substances of public health concern employing a wide range of experimental approaches, from high-throughput in-vitro test systems to chronic toxicity in rodent models. The NTP has ongoing toxicological studies focused on chemical exposures that are potentially of concern for gas extraction workers or communities impacted by natural gas extraction operations. For example, a nascent research program on PAHs aims to characterize the toxicity of a broad range of individual PAHs, defined PAH mixtures, and complex environmental mixtures containing PAHs. The program includes a short-term toxicology testing panel that incorporates in-vitro, alternative animal, and in-vivo rodent models and captures a diverse array of health endpoints (Rider, 2012).

NIEHS is also funding shale-related research through its centers program and through other external research funding mechanisms. Work under NIOSH is described above with the occupational health section.

CONCLUSION

Toxicological research identifies toxicological hazards and characterizes risks associated with human and environmental exposures to chemical substances. The development and use of toxicological information has a long history of minimizing risk to human health and the environment in our modern industrial era. The evolution of hydraulic fracturing requires sound scientific input on the identification of potential hazards, exposure assessment and risk characterization, and management of the chemicals and processes associated with this technology. Such efforts are most effective and beneficial when used in a predictive manner rather than to define toxicological causality after adverse consequences have been reported. By advancing the science, toxicologists can provide the requisite knowledge and expertise to minimize detrimental effects to human health and the environment from advanced hydraulic fracturing enterprise. Appropriate and timely integration of the science of toxicology into the larger public and governmental discussions of this enterprise is critical to a rational and balanced outcome that protects public and environmental health and ensures progress for cleaner energy development.

FUNDING

National Institute of Environmental Health Sciences (NIEHS) P30-ES013508 (T.M.P., in part).

We gratefully acknowledge the excellent assistance of Martha Lindauer and Jade Coley. Conflict of interest: B.D.G. has served as a public health expert for the City of Morgantown, W.V. on the judicial issue of whether hydraulic fracturing could be prohibited.

REFERENCES

Comments